The Winery

Where Science Meets Art

Wine Making...

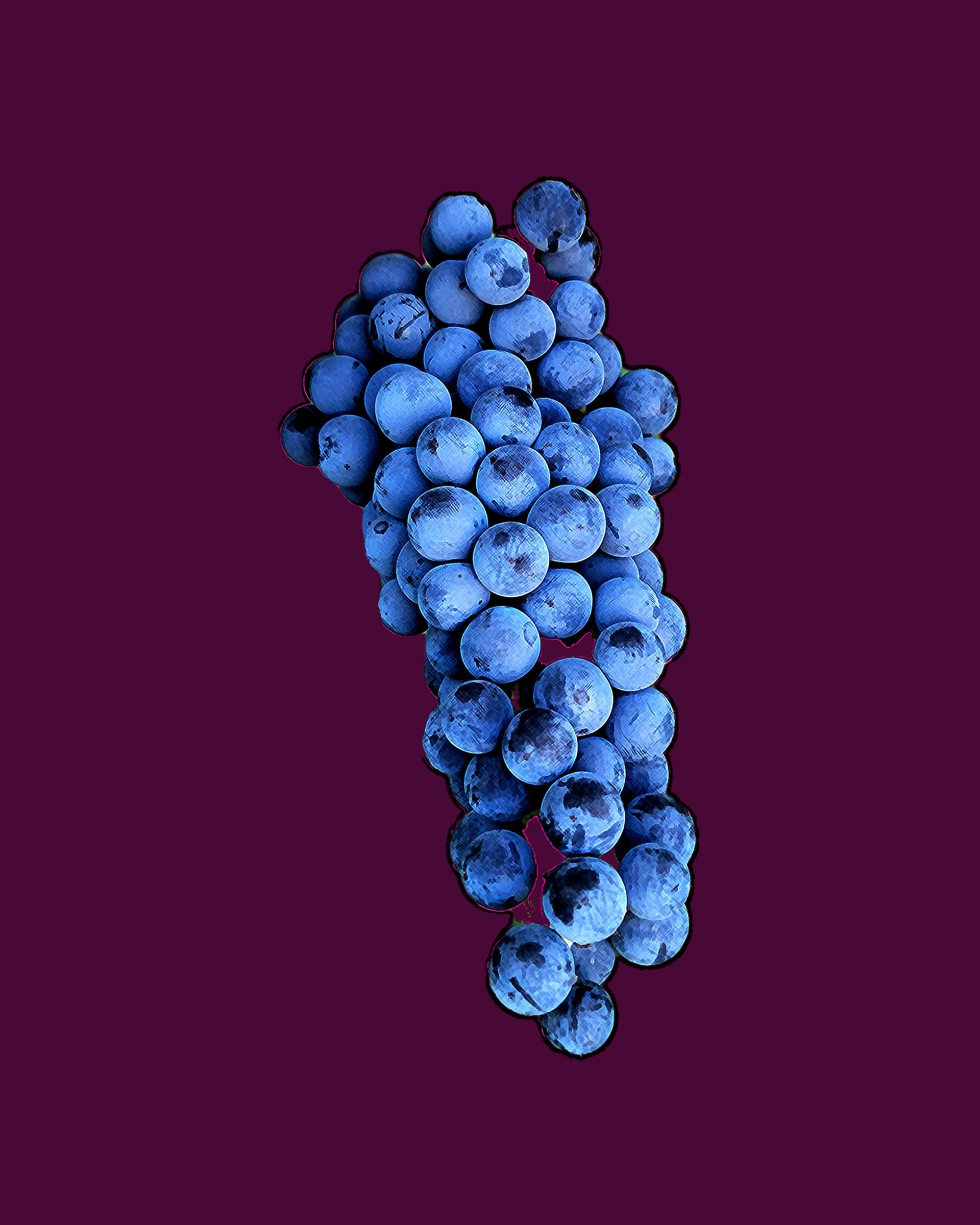

We started making wine many years ago, now, and were frustrated that the most important component was not available here...GRAPES!

There were none to be had locally! We didn’t want grapes transported days on a truck from California, or juice from vineyards that freeze and later sell the stuff they don’t want. Many wineries import grapes, frozen juice, or finished wine from other regions.

That is not the case here!

No, we wanted fresh, cool, grapes picked early in the morning and processed right away - not days, weeks, or months later.

All of the wine made and sold at Inland Ocean Vineyards is from the grapes grown on the property.

More About The Winery

There are many intricacies to making wine. But, read any book on wine making and they will tell you that good wine is made in the vineyard and one of the most important things in the vineyard are the steps of the winemaker. We hope that to be true because we have tens of thousands of steps in our vineyard.

Many decisions about the wines are made long in advance of harvest:

- What yeast (there are hundreds) will best fit a particular grape variety?

- What will its percent alcohol tolerance and its aroma profile be?,

- How it will work with malolactic fermentation?

- What temperature to ferment?

- Which yeast nutrients are best for the yeast selected?

- Which type of containers, which oak and for how long?

And so many other factors to consider that have to be ready the moment the grapes arrive from the field.

Once harvested, the grapes are crushed, pressed, and refrigerated to allow bulk sediment to settle out. The juice is then pumped into clean tanks and fermented.

Over the next few weeks, sugar content, acid pH, and sulfur are monitored until fermentation is complete.

Racking the good wine off the tops and into new containers is a constant process, along with cleaning and sterilizing many tanks for many months.

The wine is then protein stabilized and cold stabilized, filtered, and sent to the lab for analysis.

If all looks good, it’s time for bottling, capping and labeling!

We will bottle about 3200 bottles this year, and we hope you will come join us for a taste of wonderful Kansas grown and produced wine.